We are firmly convinced that water cannot burn - this seems to be contrary to all dogmas and canons theoretical physics. However, real facts and practice say otherwise!

The discovery was made by a physician from the University of Erie, John Kanzius (John Kanzius) - when trying to desalinate sea water using a radio frequency generator, developed by him for the treatment of neoplasms. During the experiment, a tongue of flame suddenly escaped from the sea water! Subsequently, a similar desktop experiment was put by an employee of the University of Pennsylvania Rustum Roy (Rustum Roy).

The physics of the process of burning salt water, of course, is largely incomprehensible. Salt is absolutely necessary: in distilled water, the "Cansius effect" has not yet been observed.

According to Kanzius and Roy, burning occurs as long as the water is in the radio field (that is, as long as favorable conditions are maintained for the decay of water), temperatures above 1600 degrees Celsius can be reached. The temperature of the flame and its color depends on the concentration of salt and other substances dissolved in water.

It is believed that the covalent bond between oxygen and hydrogen in a water molecule is very strong, and in order to break it, considerable energy is needed. A classic example of the splitting of a water molecule is electrolysis, a fairly energy-intensive process. Kanzius, however, emphasizes that in this case it is not electrolysis that takes place, but a completely different phenomenon. What frequency of radio waves are used in the device, is not reported. Some of the water molecules in the solution are, of course, in a dissociated form, but this does not help to understand what underlies the ongoing process.

Based on the ideas of official science, one has to admit various frills: that during combustion it is not water that is formed, but hydrogen peroxide, that oxygen is not released in the form of a gas (and only oxygen from the air goes to combustion), but reacts with salt, forming, for example , ClO3- chlorates, etc. All these assumptions are fantastic, and most importantly, they still do not explain where the extra energy comes from.

From point of view modern science it turns out to be a very funny process. Indeed, according to official physicists, in order to launch it, it is necessary to break the hydrogen-oxygen bond, to expend energy. Subsequently, hydrogen reacts with oxygen and again gives water. As a result, the same bond is formed, during its formation, of course, energy is released, but it cannot in any way be greater than the energy expended on breaking the bond.

It can be assumed that in fact water is not a renewable fuel in the Kanzius apparatus, that is, it is spent irreversibly (like firewood in a fire, coal in a thermal power plant, nuclear fuel in a nuclear power plant), and the output is not water, but something else. Then the law of conservation of energy is not violated, but it does not become easier.

Another possible energy source is the dissolved salt itself. The dissolution of sodium chloride is an endothermic process that takes place with the absorption of energy, respectively, at reverse process energy will be released. However, the amount of this energy is negligible: about four kilojoules per mole (about 50 kilojoules per kilogram of salt, which is almost a thousand times less specific heat gasoline combustion).

Moreover, none of the supporters of the project directly stated that the output energy can exceed the input energy, it was only about their ratio.

In fact, from the point of view of the unified field theory, there is no inexplicable contradiction in the fact that water burns. In fact, here we are talking about its decay into elementary ethereal components with the release of a large amount of heat. That is, under the influence of the flow of ether (primary matters) of radio emission, water becomes unstable and begins to disintegrate into primary components, which is perceived as combustion. The presence of salts makes it possible to simplify this process - water can decay without them, but this will require more powerful radio emission with a different frequency. In ancient times, it was well known that everything in the world has a single nature, all the elements - fire, water, air, and earth (stone). This means that one thing can turn into another under other conditions - salt water breaks up with the release of a flame and high temperature, but who said that the reverse process is impossible?

Everyone who regularly uses stove heating is well aware of the typical disadvantages of this method.

This:

1. Overgrowth chimney soot, or even tar.

2. Large heat loss through the chimney.

3. Problems with the use of damp and rotten firewood. (Without an open blower they do not burn)

4. Thick smoke from the chimney.

5. a large amount of not completely burned out ash.

All these shortcomings are easily eliminated if you heat the stove with water. And it's not a joke.

What is the essence of the proposed improvement? The thing is that water vapor at temperatures above 600 ° C behaves like a fuel. More precisely, in the presence of carbon, water reacts with it and as a result water gas is formed - a mixture of hydrogen and carbon monoxide. H2O+C ↔ H2+CO. This is a reversible reaction, and the higher the temperature, the more it shifts towards the formation of water gas. In the presence of free oxygen, water gas burns to form H2O+CO2. Moreover, at temperatures approaching 1000 ° C, water simply decomposes into hydrogen and oxygen. That is why it is not recommended to extinguish strong fires with water. While the water heats up and evaporates, it takes a large amount of heat and acts as a "quencher", but if the steam heats up above 600 ° C, additional fuel is obtained. Those. water effectively extinguishes a fire only if there is a lot of it compared to the heat source. For the same reason, it is almost useless to put out a strong fire with snow.

The problems with damp wood are due to the fact that a large amount of heat must be applied to a relatively small surface of firewood in order to heat the tree to a temperature of more than 300 ° C plus evaporate the water contained in the tree plus supply a sufficient amount of free oxygen, which is only 23% in air, and the rest is an inert gas, which also needs to be heated.

A completely different picture is obtained if an external source of superheated steam is used. In this case, the flow of superheated steam in contact with the surface of the wood reacts with carbon and moves further in the form of water vapor, making room for the next portions of steam. The combustion of water gas occurs at a distance from the surface of the tree and in a much larger volume, where the probability of encountering free oxygen is much higher.

Of course, it is possible to create a design of a stove with electric auto-ignition of firewood, including raw firewood. But this will be a relatively complex construction, and in the first approximation this is not required. All that is required in the simplest version is to make a container the size of a blower from a sheet of roofing iron, or from other tin. The box is made without any special tricks, by bending the side faces of the simplest sweep.

To ensure the tightness of the joints, they are poured with ordinary hot-melt adhesive (one stick of glue is enough, you can do without a hot-melt gun). The melting point of the glue is 150°C and this is quite enough to prevent water from flowing out. You can try to pick up a ready-made container. It is desirable that the capacity is 3-5 liters. Then the water supply will be enough for 2-3 hours of heating. If you have a Burelyan-type stove, without a blower, you can install a container with water inside the furnace, but this is not so convenient.

With this, the simplest improvement, the stove is fired up as usual, using a small amount (1-2 kg) of dry firewood. When these firewood flare up, you can already put any firewood. When the water starts to work, the smoke from the pipe becomes invisible, only the trembling of hot air is visible. From this moment on, the blower can and should be closed deafly. Firewood, in the presence of water, usually burns completely. The flame burns quietly, and the flow of evaporating water is sufficient to support the combustion process. If the stove provides a high degree of tightness, then it may be necessary to slightly open the blower, but this is not required for me. The amount of ash removed is reduced by about 2-3 times. The pipe after several days of such a furnace becomes clean.

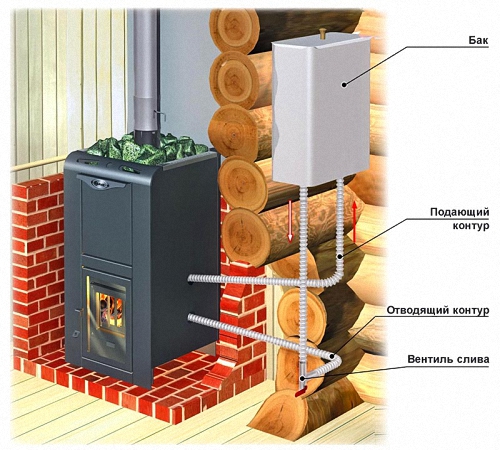

The arrangement of a stove with a water circuit in the house has a lot of advantages, primarily due to the fact that the stove not only acts as a heater, but also supplies hot water. There are many types of water ovens. We will talk about their features, advantages and manufacturing methods further.

Long-burning water furnaces - the principle of operation, advantages and disadvantages

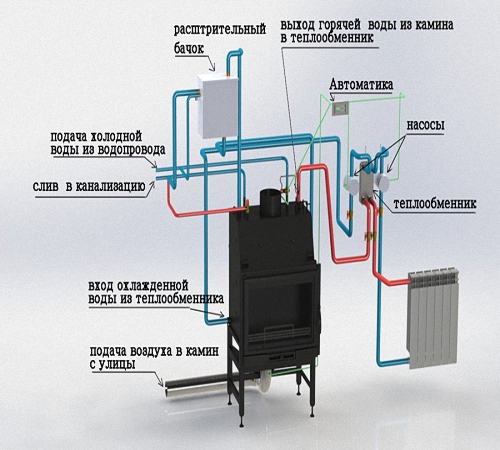

For the manufacture of this kind of furnace, boiler steel or cast iron is used. They work directly under steam pressure. water oven long burning It is used both as the main source of heating, and in combination with other heating devices.

In the inner part of the furnace there is an element in the form of a heat exchanger. It is made from metal pipes or sheet metal. The second option is more popular, as it has simplified processing, and it is easier to care for such a heat exchanger.

A good register helps to achieve maximum heating in a short time of operation of the stove. In addition, the water must be heated evenly and distributed throughout the system in the same way.

When steam passes through the channel of the system, it heats the water, thereby transferring its thermal energy. There is an option for arranging furnaces that have two or even three tanks. In this case, the level of efficiency improves significantly. In the first tank, the water is heated, and in the second it turns into steam. In order for the steam to warm up to its maximum state, it is better if the boiler has its own room.

Furnaces with a water circuit have the following advantages:

1. High level of performance - such a stove provides heat even for rooms that are too large in area.

2. Affordable cost - the price of a water circuit oven compared to alternatives low, and if you build such a furnace yourself, then its purchase will be even cheaper.

3. Variety of fuels used for space heating. Such a stove is able to work both on wood and coal, and on peat or sawdust.

4. Independence from the mains - work is carried out using solid fuel. The room and water are heated without being connected to electricity.

Among the disadvantages of a furnace with a water circuit, it should be noted:

- low efficiency compared to other types of heating;

- the need for manual control - it is required to constantly supply fuel to the system, clean it of its residues and manually control the entire process of work.

Furnaces with a water circuit for the home - arrangement

If you use the classic version of the Russian stove without a water circuit, then the heat in the room is not distributed evenly: it is hotter near the stove, and cooler away from it. Installing a water heating circuit solves this problem and it turns out to distribute heat throughout the house.

In addition, such a stove not only burns the house, but it is also possible to use it as cooking food and use hot water for your own needs.

The water circuit allows the furnace not only to heat the room during its combustion, but also to carry out this process after a certain time has elapsed after the completion of the furnace. Since the walls of the oven remain hot for a long time.

The scope of use of furnaces with a water circuit extends to the heating of private houses in rural areas, as well as for the heat supply of summer cottages, cottages and country houses. If the owners of the house opt for this type of heating, then the need to purchase expensive boilers disappears by itself. This heating option is one of the most economical.

With irregular residence in the building, it is better not to install such a heating system. Since in winter there is a risk of freezing of water in the system. Although it is possible to install an anti-freeze liquid that will solve this problem.

There are three main ways in which it will be possible to equip a furnace with a water circuit:

- purchase of finished metal stove, installation of a system under it;

- construction of a brick oven with the involvement of specialists working in this industry;

- independent production of a furnace with a water circuit.

The last two options involve the independent manufacture of a furnace boiler or heat exchanger, which is necessarily present in the water circuit.

Do-it-yourself water oven: manufacturing technology

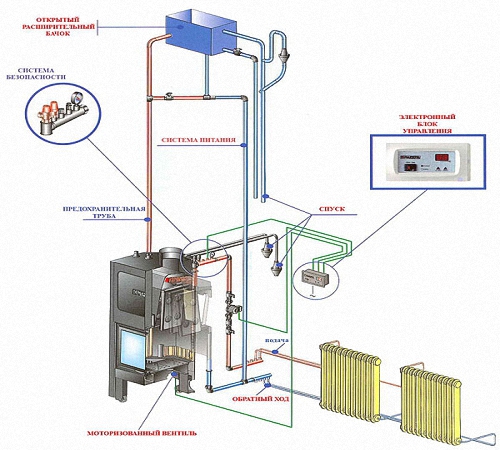

Before independent construction brick oven with a water circuit, care should be taken to prepare a heat exchanger or register, boiler or coil. It is possible to purchase one of these items. For their independent production, sheet iron or metal pipes are required.

The construction of a heat exchanger: a register or a boiler, requires special skills in working with a welding tool. It is these elements that are the main ones in the heating system with a water circuit. Since a system is connected to them, into which heat enters.

The minimum thickness of the steel used in the manufacturing process of the heat exchanger is 3 mm. The main requirement for the heat exchanger is to ensure maximum heating of the heat carrier and the uniformity of its circulation in the system.

More simple to manufacture and convenient to operate are heat exchangers based on sheet steel. Although their heating area is much smaller, in contrast to the pipe version, they are easily cleaned from fuel combustion products.

Drawing of a water furnace - heat exchanger:

Having little experience in welding, it is quite possible, according to the drawings, to make a heat exchanger with your own hands.

1. This type of heat exchanger is used in furnaces of the heating plan.

2. For its manufacture, choose steel with a thickness of 0.5 cm.

3. In addition, you will need a pipe segment, 5x6x4 cm, a rectangular profile and pipes with a diameter of 4.5 cm.

4. They will perform the function of supplying and draining water.

5. The size of the heat exchanger is calculated taking into account the heating area and the size of the stove itself.

Water stoves for the home: masonry technology

There are two options for building a brick stove with a water circuit:

- construction of a new stove, the size of which is selected according to the size of the existing heat exchanger;

- installation of a heat exchanger in a pre-built furnace, then a type of heat exchanger should be built that will be compatible with the existing furnace.

Please note that the distance between the stove and the heat exchanger must be at least 4 cm, otherwise the water in it will boil, which will lead to the destruction of the entire system.

If the system uses circulation pump, then the distance is reduced to 25-30 mm. The thickness of the walls of the heat exchanger should be 0.3-0.5 cm. If the walls are smaller, then they will burn out, if more, then the fuel consumption will increase.

For efficient heating of the heat exchanger and in order to compensate for the thermal expansion of steel, it is necessary to take care of a gap of one centimeter, which will compensate for this expansion.

If the heat exchanger is made of pipes, then the gap should be more than one centimeter. Thus, it will be possible to heat the thermal register more qualitatively. In addition, maintenance and cleaning of the stove will be facilitated.

When arranging stoves that have a heating and cooking purpose, it is necessary to provide for the function of removing the stove to clean the heat exchanger, since ash accumulates in the space between it and the stove, which adversely affects the performance of the entire system.

Brick laying of the furnace is carried out by specialists with experience in this field. The performance of these works by a person who does not have experience will lead to wrong work the entire system. If it is planned to carry out work without the involvement of specialists, then a special scheme should be used, which indicates the correctness of the entire masonry.

The brick is connected to each other with a solution of clay and sand. If there are certain irregularities or sharp transitions, then with the help of a grinder, cut off a small plate of brick and install it in the place where there is a transition. Do not cover this area with clay, as it will still crumble during operation.

After the stove has completely dried, the process of installing a heat exchanger in it follows. There are two options for doing this work.

The first method involves the in-place installation of the heat exchanger. It is allowed for heating and cooking or cookers that have a tiled surface. In this case, the top cover is removed and a heat exchanger is installed in the stove. A hole is made in the wall of the firebox, in which the pipes leading to the register section are located.

The second option involves disassembling the upper section of the stove. This method is more widespread than the previous one. After installing the register appearance oven does not change.

When carrying out this operation, it is possible to change the number of channels and the system. For self-assembly of the heat exchanger according to the second method, when disassembling the furnace, draw a diagram showing the location of the bricks. Please note that during the disassembly process there is a risk of damage to the bricks, if this happens, worry about replacing them.

Furnace with water heating photo:

Manufacturing technology of a wood-burning water stove

Let's take a look at the equipment cast iron oven with water line. For the manufacture of the water circuit of the stove, you will need old radiators, which can be purchased on the construction market. Before use, care should be taken to clean, rinse and disassemble them. For cleaning radiators, it is better to give preference to hydrochloric acid.

After reading all the sections, the process of assembling them follows. During the assembly process, replace the old cardboard gaskets with asbestos. The design is assembled in such a way as to place the outlet pipe at the top, and the entrance at the bottom.

This design is located in the chimney, next to the firebox. Water is heated with hot gases and thus not only the room in which the stove is installed is heated, but the whole house.

Before checking the performance of the system, you should pay attention to leaks and, if any, eliminate them. It is better to give preference to radiators made of cast iron. It is possible to manufacture a water circuit using steel pipes, but then they should be thick enough.

With the help of a water circuit, any stove is tied. A variant of equipment and an additional boiler installed in the chimney is possible. Thus, water is heated much faster.

Another option for manufacturing a furnace with water heating involves the manufacture of a pyrolysis boiler, which has two sections. This system has a higher efficiency, since the gases do not move through the system immediately to the chimney.

As a piping for the boiler, thick-walled pipes are used, through which water circulates. Please note that in order for the boiler to function normally, firewood should be used as fuel, exclusively with a low moisture content.

It is possible to arrange a system through which not water, but steam moves. Such a system can also heat not only one room, but the whole residential building.

The water fireplace has the appearance of a metal firebox, with compacted walls from 4 to 6 mm. The heat exchanger is located inside the fireplace. There is water in the main system, the average is 40 liters. Water heating occurs due to the energy that appears as a result of fuel combustion.

The piping system is connected to heating system, and thus, hot water is supplied to the whole house. In addition, in this system there are sensors responsible for adjusting the temperature on the fireplace.

Among the advantages of modern fireplace stoves with a water circuit, it should be noted:

- affordable cost compared to boilers;

- the ability to combine with other types of heating devices;

- variety of fuel that is suitable for use;

- presentable appearance;

- the possibility of installation in rooms for various purposes;

- no need for power supply;

- autonomy of use.

Furnaces with a water circuit video: