Self-installation of the heating system of a private house at first may seem very difficult. However, nothing is impossible. The main thing is to correctly understand the basic principles of this process and carefully prepare for it.

Correct installation heating a cottage or house begins with an accurate calculation required power heating equipment and choosing the most efficient heating system option in a particular case. In order not to be mistaken, you need to get expert advice. Correcting mistakes will be very difficult and expensive.

In residential buildings of the private sector, the installation of heating systems is done individually. The main component of the system is a liquid, steam or gas that transfers heat to the heating devices through pipes. Steam heating is based on the circulation of steam generated when water is heated. Turning into condensate, the steam moves from the heaters to the boiler, then heats up again. Such a system has little efficiency, creating many problems. Therefore, now steam heating in residential buildings is prohibited.

Air heating is, first of all, a "warm floor". It requires significant energy costs, the installation of this system is not always possible.

![]()

Water heating is the most convenient and efficient way to heat private house. Installation of heating of this type can be carried out independently.

Water heating

Installation of heating, water supply, sewerage in a cottage or house under construction is carried out in parallel. Since the technologies are similar, the tools and equipment required are the same.

To equip heating with a liquid coolant, you need:

- hot water boiler;

- a circular hydraulic pump that drives liquid through the system from the boiler to the radiator; antifreeze requires a larger pump;

- a damper tank regulates the flow of fluid due to an elastic membrane that flexes under water pressure;

- the circuit of the heating system consists of batteries and pipes for supplying heated water;

- heating appliances - batteries, etc.;

- primary measuring transducers (sensors and regulators) to control the internal temperature and ensure uninterrupted heating operation.

To work, you need the following tools:

- electric drill or hammer drill;

- hammer;

- screwdriver;

- roulette;

- building level;

- wrench set.

Varieties of boilers

The type of heating boiler is determined by the fuel on which it operates. To choose the right energy source, you need to familiarize yourself with the main characteristics of boilers of various categories.

Installation of heating boilers operating on briquettes or pallets, i.e. solid fuel, is usually carried out in buildings with an area of \u200b\u200bno more than 100 m². Solid fuels - peat, firewood, pallets or coal, are affordable. However, it requires storage space. After all, the combustion chamber solid fuel boiler should be filled every 10-12 hours. This boiler requires periodic cleaning.

Pyrolysis - modern version solid fuel. The pyrolysis boiler can work without manual filling for several days, because the fuel is supplied automatically. The efficiency of heating on pyrolysis is increased due to the combustion of not only fuel, but also the emitted gas.

Liquid fuel - kerosene, diesel or fuel oil, is more often used in the steppe regions. Liquid fuel boilers do not require frequent loading. They are cast from cast iron, so they are quite heavy. It is necessary to store the fuel supply in accordance with GOST 1510-84.

In the presence of a gas main, it is more expedient to install a gas heating boiler. Gas is the cheapest fuel. If there is no central gas supply in the house, it is possible to install heating boilers running on bio- or liquefied gas. Such boilers must be registered with Rostekhnadzor. They should only be installed by specialists.

The main scheme of the residential heating system

Single-circuit water boilers are used only for space heating. For hot water supply, a special boiler is installed. Due to the two-circuit system, heating and hot water supply are provided.

Wiring without circulation does not ensure the removal of cooled water. Batteries heat up unevenly. The temperature in them drops as they move away from the boiler. The efficiency of such a system is low, it is almost impossible to set the required temperature.

The heating system assumes that heat losses are minimized, and heat transfer remains maximum. You also need to take into account the amount of materials used, the model of the boiler and the type of batteries when designing the system. To carry out such a project yourself, it is not necessary to have the appropriate training, it is enough to know some rules, following which you can successfully prepare and install heating in a private house with your own hands.

Before buying materials and getting ready to work, first decide what type of heating system you will use, select a suitable boiler and radiators for it. After that, it is necessary to draw up a project and only then proceed to the acquisition of materials and installation.

IMPORTANT! This article discusses the water heating system, which includes a boiler, pipes and radiators. This design is the most simple, reliable and less expensive to operate. The system works like this: water is heated in the boiler, it enters the radiators through pipes, the latter give off the received heat to the room. The cooled liquid through the pipes (return) enters the boiler again, and the process is repeated.

Schemes for installing a heating system in a private house

In practice, two types of systems are used - schemes (or types of piping), namely:

- single-pipe;

- two-pipe.

Each of them has its own advantages, disadvantages and is used in different cases.

Single pipe system

This type of wiring is cheaper and simpler. The system is built in the form of a ring - all batteries are connected in series with each other, and hot water moves from one radiator to another, then enters the boiler again.

As can be seen in the figure, all batteries are connected in series, and the coolant passes through each of them.

This heating scheme is very economical in its design, it is easy to install and design. But it has one significant drawback. It is so weighty that many refuse such wiring and prefer the more expensive and complex - two-pipe. The problem is that as the coolant advances, it will gradually cool down. Until the last battery, the water will flow a little warm. If you increase the boiler power, then the first radiator will heat the air too much. Such an uneven distribution of heat makes it necessary to abandon a simple and cheap one-pipe system.

You can try to get out of a difficult situation by increasing the number of sections of the last radiator, but this is not always effective. This suggests the conclusion that single-pipe wiring can be used when the number of batteries connected in series is no more than three.

Some get out of the situation as follows: they connect a pump to the boiler, thereby forcing the water to move forcibly. The liquid does not have time to cool down and passes through all the radiators, almost without losing temperature. But in this case, you are waiting for some inconvenience:

- the pump costs money, which means that the cost of installing the system is growing;

- electricity consumption increases, since the pump is powered by electricity;

- if the electricity is cut off, there will be no pressure in the system, which means there will be no heat.

Output. A single pipe system is only effective for small houses with 1-2 rooms, where a small number of radiators are used. Despite its simplicity and reliability, it does not justify itself in country houses where you need to install more than three radiators for the entire living area.

Two-pipe system

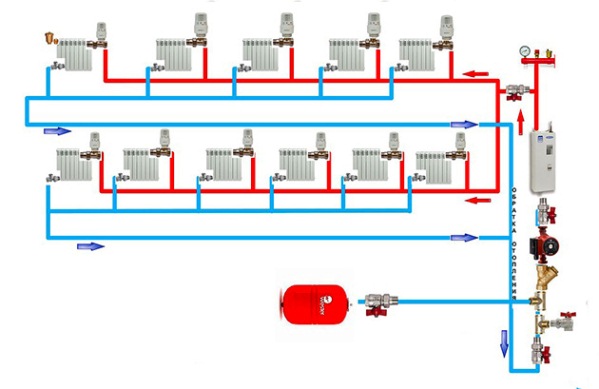

Hot water is supplied through one pipeline, and cooled water through another. This ensures even distribution of heat across all batteries.

Such a heating layout in a private house will be much more efficient and better than a single-pipe one. Although it is more expensive to perform and more difficult to install, it allows you to evenly distribute heat across all batteries, which will help create comfortable conditions. Unlike a single pipe, in this wiring a pipe with hot water is supplied under each radiator, and the cooled liquid descends through the return line into the boiler. Since the coolant is supplied immediately to all batteries, the latter heat up equally.

This system is not much more complicated than the first, you will have to buy more materials, since you will have to bring pipes to each radiator.

A two-pipe system can work in two ways:

- collector;

- ray.

The beam version of the wiring is older. In this option, the supply pipe is installed at the top of the house, after which the pipes are routed to each battery. Thanks to this design, the circuit got the name - beam.

The first scheme works as follows: in the attic it is necessary to install a collector (a special device consisting of many pipes), which distributes the coolant through the heating pipes. In the same place, you need to install shut-off valves, which will cut off the contours. This design is quite convenient, it facilitates the repair of the entire line and even a separate radiator. Although the circuit is reliable, it has one significant drawback - complex installation with a large number of materials (stop valves, pipes, sensors, control devices). The collector wiring diagram for heating pipes is similar to the radial one, but more complex and efficient.

Unlike a single-pipe system, a two-pipe system does not require additional forced circulation of the coolant. It shows high efficiency even without a pump.

Choosing equipment for heating a private house

In places where there are interruptions in the supply of the main type of fuel, it is recommended to install universal heating boilers.

There is a huge range of boilers on the market. Even hybrid boilers have appeared, capable of operating, for example, both on gas and wood. So, the choice depends purely on your preferences and needs. Of course, boilers with a full set of automation and hybrids will be more expensive. The former will more than pay off with their high efficiency, and the latter with their versatility.

It is impossible to advise a specific model, since different devices have different power. Choose the device that best suits your needs, however, try to select the boiler so that its operation is not costly. If you use wood, then it is better to choose a model on wood. If gas is connected, then use the gas model.

We draw up a heating project

To conduct heating in a private house with your own hands, you need a project. It must be compiled in the following order:

- First make a sketch of the house.

- Then carry out zoning of the house and determine the degree of comfort of each room.

- Calculate the heat loss for all rooms separately.

- Design the placement of batteries in each room.

- Determine the number of sections required for each radiator.

- Select a heating scheme.

- Calculate the power of the boiler, the required amount of materials (footage of pipes, the number of tees, valves, automation, etc.).

There shouldn't be any problems with the sketch of the house, so let's go straight to the comfort zones.

IMPORTANT! It is extremely difficult to do the entire amount of work on your own, so we recommend that you find out the prices for installing heating in a private house in various companies. So, it will be easier for you to figure out which work can be given to the masters, and which is better to do yourself.

Zoning premises

Proper distribution of heat will not only make you feel comfortable at home, but can also save some money. So, what temperature is better to withstand in different rooms:

Properly plan the thermal zones of your home for a comfortable stay in it.

- The overall comfort temperature should be between 20-24 degrees.

- For the bedroom, it is better to slightly increase the temperature and set it within 22-25 degrees.

- For the bathroom, bathroom, guest room and rooms where you are most of the time, the temperature range will be from 21 to 24 degrees.

- For the dining room, kitchen, study, it is better to reduce the temperature to 18-22 degrees.

- For the hallway, garage and walk-through zone, you can set a limit of 12 degrees.

Calculate heat loss

The calculation can be simplified without taking into account the internal heat transfer between rooms. When calculating, it is important to determine the number of external walls and corners, it is there that the greatest losses occur. The amount of loss can be calculated by taking the data from the table below and multiplying it by the thickness of the wall.

By thermal resistance

| Wall material and thickness | Rt |

|---|---|

| Brick wall 3 bricks thick (79 cm) | 0,592 |

| Brick wall 2.5 bricks (67 cm) thick | 0,502 |

| Brick wall 2 bricks thick (54 cm) | 0,405 |

| Brick wall 1 brick thick (25 cm) | 0,187 |

| Log cabin diameter 25 cm | 0,55 |

| Log cabin diameter 20 cm | 0,44 |

| Log house from a bar 20 cm thick | 0,806 |

| Log cabin from a bar 10 cm thick | 0,353 |

| Frame wall (board + mineral wool + board) 20 cm | 0,703 |

| Foam concrete wall 20 cm | 0,476 |

| Foam concrete wall 30 cm | 0,709 |

| Plaster 2-3 cm | 0,035 |

| Ceiling (attic) ceiling | 1,43 |

| wooden floors | 1,85 |

| Double wooden doors | 0,21 |

According to the given heat losses

Specific heat loss of building fencing elements (per 1 m 2 along the inner contour of the walls) depending on the average temperature of the coldest week of the year

| Fencing characteristics | Outside temperature, °C | Heat losses, W / m 2 |

|---|---|---|

| Window with double glazing | -24 | 117 |

| -26 | 126 | |

| -28 | 131 | |

| -30 | 135 | |

| Solid wood doors (double) | -24 | 204 |

| -26 | 219 | |

| -28 | 228 | |

| -30 | 234 | |

| Attic floor | -24 | 30 |

| -26 | 33 | |

| -28 | 34 | |

| -30 | 35 | |

| Wooden floors above basement | -24 | 22 |

| -26 | 25 | |

| -28 | 26 | |

| -30 | 26 |

IMPORTANT! A lot of heat escapes through the windows.

Batteries

The choice of radiators is very important. Not only the durability of the heating system depends on this, but also the degrees of heat in your home. There are only 4 types of batteries:

- cast iron;

- steel;

- aluminum;

- bimetallic.

Bimetal radiators consist of strong steel pipes and an aluminum jacket that gives off heat well.

Best of all they give off heat, they last the longest - cast-iron radiators. But they are difficult to install due to their significant weight. Bimetallic batteries are an excellent choice.. They are durable, give off heat well, but are more expensive than other options. It is better not to install aluminum and steel, as aluminum is short-lived, and steel will not be able to cope with the heating of rooms in severe frost.

To correctly calculate the number of radiator sections per room, you need to multiply the number of heat losses by 1.2 (the safety factor) and divide by the thermal power of the battery section. The value must be rounded up.

On a note! Alternative option. In order not to complicate yourself with calculations, you can calculate the number of sections like this: for every 2 sq. m of a room (with a ceiling height of up to 3 m) one section is needed. If the heat loss is high, then take a couple of sections in reserve.

The principle of operation of the "screen" for the battery.

Batteries are best placed under a window. Such a move will somewhat reduce heat loss through the window opening. But in this case, the battery will give off some of its heat to the wall, which you do not need at all. That's why we recommend to mount a "screen" on the wall where the radiator is installed. It is usually made of foil and serves as a heat reflector. The warm stream is reflected and returned to the room, while heating the air, and not the wall.

After all the calculations, you need to choose the heating scheme, which was already mentioned earlier. Our choice is unchanged - we recommend a two-pipe.

Boiler power calculation

It is worth noting that it is better to take the power parameter with a small margin, so you protect yourself in severe frost. heating device deal with emergency situations calmly.

To calculate the power, you need to add up the power of all radiators (possibly other devices that will be powered by the boiler), multiply this value by 1.4 (this is a coefficient that takes into account heat loss for ventilation). The resulting figure must be divided by the power utilization factor and the efficiency of the boiler. Then choose the boiler from the table that best matches the resulting value.

Latest blanks

When all the calculations are done, you need to measure all the distances in order to buy the right amount of pipes, tees. Take everything with a small margin. Buy a boiler, coordinate everything Required documents, buy radiators and other consumables.

We carry out heating installation in a private house

One of the options for a properly planned boiler room.

The heating system is installed in several stages. First of all, you need to equip the room for the boiler. It must be well ventilated, treated with refractory materials.. The boiler itself is not mounted close to the wall, but with a slight indent. You also need to retreat from the ceiling, floor and other walls. Hang the appliance so that it is easy to reach.

After installing the boiler, proceed to connect the pump (if needed) or install the collector (if provided). Also secure all controls and measuring instruments near the boiler. Only after the above actions should proceed to the arrangement main pipelines. Here you can not do without a perforator, since for laying the line you will have to punch holes in the walls.

Important! The slope must be at least 5 mm per meter - it is very important to withstand the slope. The absence of such a negative impact on the operation of the entire system as a whole, so take this issue responsibly.

Schematic representation of the correct slope in the heating system. Water flows by gravity into the radiators and is sent back to the boiler by gravity.

Radiators are installed last. Before installation, you need to mark the wall, then drill holes where the brackets are installed. When marking, observe the following distances: from the floor to the underside of the battery - at least 10 cm, from the wall to the back wall - at least 2 cm, and from the window sill - at least 10 cm. It is advisable to install valves on all inputs and outputs of the batteries, which will simplify replacement or repair.

Only after all work is completed, you can check the system. If you installed a gas boiler, be sure to call a representative of the gas service for a trial run.

In fact, installing a heating system in a private house is not so difficult. It is enough to follow all the rules and work without haste. The problem is just timing. If you do not have too much time, then look at the prices for the work, figure out what you can do on your own, and what is better to entrust to the masters. Thus, you will save time and money. Buy high-quality materials, then all the elements will last you much longer. Also install good radiators, they will have greater efficiency, which means that fuel costs will be reduced.

Video "Do-it-yourself heating wiring in a private house"

Properly organizing the heating of the house is not an easy task. It is clear that specialists – designers and installers – will deal with it best. It is possible and necessary to involve them in the process, but in what capacity it is up to you, the owner of the house, to determine. There are three options: hired people perform the entire range of activities or part of these works, or act as consultants, and you do the heating yourself.

Regardless of which heating option is chosen, it is necessary to have a good understanding of all stages of the process. This material is a step-by-step guide to action. Its goal is to help you solve the heating problem yourself or competently control the hired specialists and installers.

Elements of the heating system

In the vast majority of cases, private residential buildings are heated by water heating systems. This is a traditional approach to solving the issue, which has an undeniable advantage - universality. That is, heat is delivered to all rooms by means of a heat carrier, and it can be heated using various energy carriers. We will consider their list below, when choosing a boiler.

Water systems also provide an opportunity to organize combined heating using two or even three types of energy carriers.

Any heating system, where the coolant serves as a transmission link, is divided into the following components:

- heat source;

- pipeline network with all additional equipment and fittings;

- heating devices (radiators or heating circuits for underfloor heating).

For the purpose of processing and regulating the heat carrier, as well as performing maintenance work in heating systems ah, additional equipment and shut-off and control valves are used. The equipment includes the following items:

- expansion tank;

- circulation pump;

- hydraulic separator (hydraulic arrow);

- buffer capacity;

- distribution manifold;

- boiler indirect heating;

- devices and means of automation.

Note. An obligatory attribute of a water heating system is an expansion tank, the rest of the equipment is installed as needed.

It is well known that when heated, water expands, and in a confined space, its additional volume has nowhere to go. In order to avoid rupture of connections from increased pressure in the network, an expansion tank of an open or membrane type. She also accepts excess water.

Forced circulation of the coolant is provided by a pump, and in the presence of several circuits separated by a hydraulic arrow or buffer capacity, 2 or more pumping units are used. Concerning buffer tank, then it works simultaneously as a hydraulic separator and a heat accumulator. The separation of the boiler circulation circuit from all the others is practiced in complex cottage systems with several floors.

Collectors for the distribution of the coolant are installed in heating systems with underfloor heating or in cases where a beam scheme for connecting batteries is used, we will talk about this in the following sections. An indirect heating boiler is a tank with a coil, where water for the needs of domestic hot water is heated from the coolant. Thermometers and pressure gauges are installed in the system for visual control of the temperature and pressure of water in the system. Automation tools (sensors, thermostats, controllers, servo drives) not only control the coolant parameters, but also regulate them automatically.

Shut-off valves

In addition to the above equipment, water heating the house is controlled and maintained using shut-off and control valves, shown in the table:

When you have familiarized yourself with what elements the heating system consists of, you can proceed to the first step towards the goal - calculations.

Calculation of the heating system and selection of boiler power

It is impossible to select equipment without knowing the amount of thermal energy required to heat the building. It can be determined in two ways: simple approximate and calculated. All sellers like to use the first method heating technology, since it is quite simple and gives a more or less correct result. This is the calculation of thermal power by the area of heated premises.

They take a separate room, measure its area and multiply the resulting value by 100 watts. The energy required for the entire country house is determined by summing the indicators for all rooms. We offer a more accurate method:

- by 100 W multiply the area of those rooms where only 1 wall is in contact with the street, on which there is 1 window;

- if the room is a corner room with one window, then its area must be multiplied by 120 W;

- when the room has 2 exterior walls with 2 or more windows, its area is multiplied by 130W.

If we consider the power as an approximate method, then residents of the northern regions of the Russian Federation may receive less heat, and the south of Ukraine may overpay for too powerful equipment. With the help of the second, calculation method, heating is designed by specialists. It is more accurate, as it gives a clear understanding of how much heat is lost through the building structures of any building.

Before proceeding with the calculations, the house must be measured, finding out the area of \u200b\u200bwalls, windows and doors. Then you need to determine the thickness of the layer of each building material from which walls, floors and roofs are built. For all materials in the reference literature or the Internet, you should find the value of thermal conductivity λ, expressed in units of W / (m ºС). We substitute it into the formula for calculating the thermal resistance R (m2 ºС / W):

R = δ / λ, here δ is the thickness of the wall material in meters.

Note. When a wall or roof is made of different materials, then you need to calculate the R value for each layer, and then summarize the results.

Now you can find out the amount of heat leaving through the external building structure, according to the formula:

- QTP \u003d 1 / R x (tv - tn) x S, where:

- QTP is the amount of heat lost, W;

- S is the previously measured area of the building structure, m2;

- tv - here you need to substitute the value of the desired internal temperature, ºС;

- tn - street temperature in the coldest period, ºС.

Important! The calculation should be made for each room separately, substituting in turn the values of thermal resistance and area for the external wall, window, door, floor and roof into the formula. Then all these results must be summed up, these will be the heat losses of this room. The areas of internal partitions do not need to be taken into account!

Heat consumption for ventilation

To find out how much heat a private house loses as a whole, it is necessary to add up the losses of all its rooms. But that's not all, because it is necessary to take into account the heating of the ventilation air, which is also provided by the heating system. In order not to go into the jungle of complex calculations, it is proposed to find out this heat consumption using a simple formula:

Qair \u003d cm (tv - tn), where:

- Qair - the desired amount of heat for ventilation, W;

- m - the amount of air by mass, is determined as the internal volume of the building, multiplied by the density of the air mixture, kg;

- (tv - tn) - as in the previous formula;

- c is the heat capacity of air masses, taken equal to 0.28 W / (kg ºС).

To determine the heat demand of the entire building, it remains to add the value of QTP for the house as a whole with the value of Qair. The power of the boiler is taken with a margin for the optimal mode of operation, that is, with a coefficient of 1.3. Here it is necessary to take into account an important point: if you plan to use a heat generator not only for heating, but also for heating water for hot water supply, then the power reserve should be increased. The boiler must work effectively in 2 directions at once, and therefore the safety factor must be taken at least 1.5.

At the moment there are different kinds heating, characterized by the energy carrier or type of fuel used. Which one to choose is up to you, and we will present all types of boilers with a brief description of their pros and cons. For heating residential buildings, you can purchase the following types of household heat generators:

- solid fuel;

- gas;

- electrical;

- on liquid fuel.

The following video will help you choose an energy source, and then a heat source:

Solid fuel boilers

They are divided into 3 varieties: direct combustion, pyrolysis and pellet. The units are popular due to the low cost of operation, because compared to other energy sources, firewood and coal are inexpensive. The exception is natural gas in the Russian Federation, but connecting to it is often more expensive than all thermal equipment along with installation. Therefore, wood and coal boilers, which have an acceptable cost, are bought by people more and more often.

On the other hand, the operation of a solid fuel heat source is very similar to simple stove heating. You need to spend time and effort to harvest, carry firewood and load it into the firebox. Serious piping of the unit is also required in order to ensure its durable and safe operation. After all, an ordinary solid fuel boiler is characterized by inertia, that is, after closing the air damper, the heating of water does not stop immediately. And the efficient use of the generated energy is possible only if there is a thermal accumulator.

Important. Boilers burning solid types fuels, generally cannot boast of high efficiency. Traditional direct combustion units have an efficiency of about 75%, pyrolysis - 80%, and pellet - no more than 83%.

The best choice in terms of comfort is a pellet heat generator, which has a high level of automation and almost no inertia. It does not require a heat accumulator and frequent trips to the boiler room. But the price of equipment and pellets often makes it inaccessible to a wide range of users.

gas boilers

An excellent option is to carry out heating that operates on main gas. In general, hot water gas boilers are very reliable and efficient. The efficiency of the simplest non-volatile unit is at least 87%, and that of an expensive condensing unit is up to 97%. The heaters are compact, well automated and safe to operate. Maintenance is required no more than once a year, and trips to the boiler room are needed only to control or change settings. A budget unit will come out much cheaper than a solid fuel one, so gas boilers can be considered publicly available.

Just like solid fuel heat generators, gas boilers a chimney device and supply and exhaust ventilation are required. As for other countries of the former USSR, the cost of fuel there is much higher than in the Russian Federation, which is why the popularity gas equipment is steadily declining.

Electric boilers

It must be said that electric heating is the most efficient of all. Not only is the efficiency of the boilers about 99%, but in addition they do not require chimneys and ventilation. Maintenance of the units as such is practically absent, except for cleaning once every 2-3 years. And most importantly: the equipment and installation are very cheap, while the degree of automation can be anything. The boiler simply does not need your attention.

As pleasant as the advantages of an electric boiler, the main drawback is just as significant - the price of electricity. Even if you use a multi-tariff electricity meter, you won’t be able to get around a wood-burning heat generator by this indicator. Such is the price for comfort, reliability and high efficiency. Well, the second minus is the absence of the necessary electrical power. Such an annoying nuisance can immediately cross out all thoughts about electric heating.

Oil boilers

At the cost of heating equipment and its installation, heating on waste oil or diesel fuel will cost about the same as on natural gas. Their performance indicators are also similar, although, for obvious reasons, working out loses somewhat. Another thing is that this type of heating can be safely called the dirtiest. Any visit to the boiler room will end at least with the smell of diesel fuel or with dirty hands. And the annual cleaning of the unit is a whole event, after which you will be smeared with soot to the waist.

The use of diesel fuel for heating is not the most profitable solution; the price of fuel can hit your pocket hard. Waste oil has also risen in price, unless you have some cheap source of it. This means that it makes sense to install a diesel boiler when there are no other energy sources or, in the future, supplying main gas. The unit easily switches from diesel fuel to gas, but the mining furnace cannot burn methane.

Schemes of heating systems for a private house

Heating systems implemented in private housing construction are one- and two-pipe. It's easy to tell them apart:

- according to a single-pipe scheme, all radiators are connected to one collector. It is both a supply and a return, passing by all the batteries in the form of a closed ring;

- in a two-pipe scheme, the coolant is supplied to the radiators through one pipe, and returns through the other.

The choice of a heating system scheme for a private house is not an easy task, it certainly does not hurt to consult a specialist. We will not sin against the truth if we say that the two-pipe scheme is more progressive and reliable than the one-pipe one. Contrary to popular belief about the low installation costs when installing the latter, we note that it is not only more expensive than a two-pipe one, but also more difficult. This topic is covered in great detail in this video:

The fact is that in a single-pipe system, the water from the radiator to the radiator cools more and more, so it is necessary to increase their capacity by adding sections. In addition, the distribution manifold must have a larger diameter than the two-pipe distribution lines. And the last thing: automatic control with a single-pipe circuit is difficult due to the mutual influence of the batteries on each other.

In a small house or cottage with up to 5 radiators, you can safely implement a single-pipe horizontal scheme (common name - Leningradka). At more heating appliances, it will not be able to function normally, because the last batteries will be cold.

Another option is to use single-pipe vertical risers in a two-story private house. Such schemes are quite common and work successfully.

The coolant with two-pipe wiring is delivered to all radiators with the same temperature, so there is no need to increase the number of sections. The division of the lines into supply and return makes it possible to automatically control the operation of the batteries through thermostatic valves.

Pipeline diameters are smaller, and the system as a whole is simpler. There are such types of two-pipe schemes:

dead-end: the pipeline network is divided into branches (shoulders), along which the coolant moves along the mains towards each other;

an associated two-pipe system: here the return manifold is, as it were, a continuation of the supply one, and the entire coolant flows in one direction, the circuit forms a ring;

collector (beam). The most expensive wiring method: pipelines from the collector are laid separately to each radiator, the laying method is hidden, in the floor.

If you take horizontal lines of larger diameter and lay them with a slope of 3-5 mm per 1 m, then the system will be able to work due to gravity (by gravity). Then the circulation pump is not needed, the circuit will be non-volatile. In fairness, we note that without a pump, both single-pipe and two-pipe wiring can function. If only conditions were created for natural circulation water.

The heating system can be made open by installing an expansion tank at the highest point that communicates with the atmosphere. This solution is used in gravity networks, otherwise it cannot be done there. If, however, an expansion tank of a membrane type is installed on the return line near the boiler, the system will be closed and operate under excess pressure. This is a more modern version, which finds its application in networks with forced movement of the coolant.

It is impossible not to say about the method of heating the house with warm floors. Its disadvantage is the high cost, since hundreds of meters of pipes will need to be laid in the screed, as a result of which a heating water circuit is obtained in each room. The ends of the pipes converge to a distribution manifold with a mixing unit and its own circulation pump. An important plus is the economical uniform heating of the premises, which is very comfortable for people. Underfloor heating circuits are unambiguously recommended for use in all residential buildings.

Advice. Owner small house(up to 150 m2) we can safely recommend adopting a conventional two-pipe scheme with forced circulation of the coolant. Then the diameters of the mains will be no more than 25 mm, the branches - 20 mm, and the connections to the batteries - 15 mm.

Heating system installation

We will begin the description of installation work with the installation and piping of the boiler. In accordance with the rules, units whose power does not exceed 60 kW can be installed in the kitchen. More powerful heat generators should be located in the boiler room. At the same time, for heat sources burning different types fuel and having an open combustion chamber, it is necessary to ensure a good air flow. A chimney device is also required to remove combustion products.

For the natural movement of water, it is recommended to install the boiler in such a way that its return pipe is below the level of the radiators on the first floor.

The place where the heat generator will be located must be chosen taking into account the minimum allowable distances from walls or other equipment. Typically, these intervals are indicated in the manual supplied with the product. If these data are not available, then we adhere to the following rules:

- passage width from the front side of the boiler - 1 m;

- if you do not need to service the unit from the side or rear, then leave a gap of 0.7 m, otherwise - 1.5 m;

- distance to the nearest equipment - 0.7 m;

- when placing two boilers next to each other, a passage of 1 m is maintained between them, opposite each other - 2 m.

Note. When installing wall-mounted heat sources, side passages are not needed, only the clearance in front of the unit must be observed for ease of maintenance.

Boiler connection

It should be noted that the piping of gas, diesel and electric heat generators is almost the same. Here it must be borne in mind that the vast majority of wall-mounted boilers are equipped with a built-in circulation pump, and many models also have an expansion tank. To begin with, consider the connection diagram of a simple gas or diesel unit:

The figure shows a diagram of a closed system with a membrane expansion tank and forced circulation. This type of binding is the most common. The pump with a bypass line and a sump is located on the return line, there is also an expansion tank. The pressure is controlled by pressure gauges, air is removed from the boiler circuit through an automatic air vent.

Note. Tying an electric boiler that is not equipped with a pump is carried out according to the same principle.

When the heat generator is equipped with its own pump, as well as a circuit for heating water for the needs of domestic hot water, the piping and installation of elements is as follows:

Shown here is a wall-mounted forced air boiler. closed cell combustion. For removing flue gases serves as a double-walled coaxial flue, brought to the street horizontally through the wall. If the furnace of the unit is open, then a traditional chimney with good natural draft is needed. How to properly install a chimney from sandwich modules is shown in the figure:

In country houses of a large area, it is often necessary to dock a boiler with several heating circuits - radiator, underfloor heating and an indirect heating boiler for hot water needs. In such a situation, the optimal solution would be to use a hydraulic separator. It will allow you to organize an independent circulation of the coolant in the boiler circuit and at the same time serve as a distribution comb for the remaining branches. Then the schematic diagram of heating a two-story house will look like this:

According to this scheme, each heating circuit has its own pump, so that it works independently of the others. Because to warm floors a coolant with a temperature of no more than 45 ° C should be supplied, three-way valves are involved on these branches. They mix hot water from the main line when the temperature of the coolant in the underfloor heating circuits decreases.

With solid fuel heat generators, the situation is more complicated. Their binding should take into account 2 points:

- possible overheating due to the inertia of the unit, the firewood cannot be extinguished quickly;

- formation of condensate when cold water enters the boiler tank from the network.

To avoid overheating and possible boiling, the circulation pump is always placed on the return line, and a safety group must be on the supply immediately after the heat generator. It consists of three elements: a pressure gauge, an automatic air vent and safety valve. The presence of the latter is crucial, it is the valve that will relieve excess pressure when the coolant overheats. If you decide to organize, then the following strapping scheme is required:

Here, a bypass and a three-way valve protect the furnace of the unit from condensation. The valve will not allow water from the system to pass into the small circuit until the temperature in it reaches 55 ° C. Detailed information on this issue can be obtained by watching the video:

Advice. Solid fuel boilers due to the peculiarities of operation, it is recommended to use it in conjunction with a buffer tank - a heat accumulator, as shown in the diagram:

Many homeowners put two different heat sources in the furnace room. They must be properly tied and connected to the system. In this case, we offer 2 schemes, one of them is for a solid fuel and electric boiler, working together with radiator heating.

The second scheme combines a gas and wood-fired heat generator that supplies heat for heating the house and preparing water for hot water supply:

To install the heating of a private house with your own hands, you first need to decide which pipes to choose for this. The modern market offers several types of metal and polymer pipes suitable for heating private houses:

- steel;

- copper;

- stainless steel;

- polypropylene (PPR);

- polyethylene (PEX, PE-RT);

- metal-plastic.

Heating mains made of ordinary "black" metal are considered a relic of the past, since they are most susceptible to corrosion and "overgrowth" of the flow area. In addition, it is not easy to carry out installation from such pipes on your own: good welding skills are needed in order to carry out a tight joint. However, some homeowners still use steel piping to this day when they arrange heating system Houses.

Copper or stainless steel tubing is a great choice, but it's too expensive. These are reliable and durable materials that are not afraid of high pressure and temperature, so if funds are available, these products are definitely recommended for use. Copper is joined by soldering, which also requires some skills, and stainless steel - using collapsible or press fittings. Preference should be given to the latter, especially with hidden laying.

Advice. For tying boilers and laying highways within the boiler room, it is best to use any kind of metal pipes.

Heating from polypropylene will cost you the cheapest. Of all types of PPR pipes, it is necessary to choose those that are reinforced with aluminum foil or fiberglass. The low price of the material is their only plus, since the installation of heating from polypropylene pipes is a rather complicated and responsible matter. And in appearance, polypropylene loses to other plastic products.

The joints of PPR pipelines with fittings are carried out by soldering, and it is not possible to check their quality. When the heating was insufficient during soldering, the connection will certainly leak later, but if it is overheated, the blurred polymer will half-block the flow area. Moreover, it will not be possible to see this during assembly, the flaws will make themselves felt later, during operation. The second significant drawback is the large elongation of the material during heating. To avoid "saber" bends, the pipe must be mounted on movable supports, and a gap must be left between the ends of the line and the wall.

It is much easier to make heating from polyethylene or metal-plastic pipes with your own hands. Although the price of these materials is higher than polypropylene. For a beginner, they are most convenient, since the joints here are quite simple. Pipelines can be laid in a screed or wall, but with one condition: the connections must be made on press fittings, not collapsible ones.

Metal-plastic and polyethylene are used both for open laying of highways, and hidden behind any screens, as well as for the installation of water-heated floors. The disadvantage of pipes made of PEX material is in its desire to return to its original state, which is why the laid heating manifold may look slightly wavy. PE-RT polyethylene and metal-plastic do not have such a “memory” and calmly bend as you need. More information about the choice of pipes is described in the video:

An ordinary homeowner, having entered a heating equipment store and seeing the widest selection of different radiators there, may conclude that choosing batteries for his home is not so easy. But this is the first impression, in fact there are not so many varieties of them:

- aluminum;

- bimetallic;

- steel panel and tubular;

- cast iron.

Note. There are also designer water heating devices of a wide variety of types, but they are expensive and deserve a separate detailed description.

Aluminum alloy sectional batteries have the best heat transfer performance, bimetallic heaters are not far from them. The difference between the two is that the former are made entirely of alloy, while the latter have a tubular steel frame inside. This is done with the aim of using the devices in the district heating systems of high-rise buildings, where pressure can be quite high. Therefore, install bimetal radiators in a private cottage does not make sense at all.

It should be noted that the installation of heating in a private house will be cheaper if you purchase steel panel radiators. Yes, their heat transfer performance is less than that of aluminum, but in practice you are unlikely to feel the difference. As for reliability and durability, the devices will successfully serve you for at least 20 years, or even more. In turn, tubular batteries are much more expensive, in this respect they are closer to designer ones.

Steel and aluminum heating appliances have one useful quality in common: they lend themselves well to automatic regulation using thermostatic valves. What can not be said about massive cast-iron batteries, on which it is pointless to install such valves. All because of the ability of cast iron to heat up for a long time, and then retain heat for some time. Also because of this, the rate of heating of the premises is reduced.

When it comes to aesthetics appearance, then the cast-iron retro radiators currently offered are much more beautiful than any other batteries. But they also cost fabulous money, and inexpensive "accordions" of the Soviet model MS-140 are only suitable for a country house. one-story house. From the above, the conclusion is:

For a private house, buy those heating devices that you like the most and suit the cost. Just take into account their features and choose the right size and heat output.

Selection by power and methods of connecting radiators

The selection of the number of sections or the size of the panel radiator is carried out according to the amount of heat required to heat the room. We have already determined this value at the very beginning, it remains to reveal a couple of nuances. The fact is that the manufacturer indicates the heat transfer of the section for the temperature difference between the coolant and the room air, equal to 70 ° C. To do this, the water in the battery must warm up to at least 90 ° C, which happens very rarely.

It turns out that the real thermal power of the device will be significantly lower than indicated in the passport, because usually the temperature in the boiler is maintained at 60-70 ° C on the coldest days. Accordingly, for proper space heating, the installation of radiators with at least one and a half heat transfer margins is required. For example, when a room needs 2 kW of heat, you must take heating appliances with a capacity of at least 2 x 1.5 = 3 kW.

Indoors, batteries are placed in places of greatest heat loss - under windows or near blank outer walls. In this case, the connection to the highways can be done in several ways:

- lateral unilateral;

- diagonal versatile;

- lower - if the radiator has corresponding pipes.

The lateral connection of the device on one side is most often used when it is connected to risers, and the diagonal one - to horizontally laid lines. These 2 methods allow you to effectively use the entire surface of the battery, which will heat up evenly.

When a one-pipe heating system is installed, the bottom versatile connection is also used. But then the efficiency of the device decreases, and hence the heat transfer. The difference in surface heating is illustrated in the figure:

There are models of radiators, where the design provides for the connection of pipes from below. Such devices have internal wiring and in fact they have a one-sided side circuit. This is clearly seen in the figure, where the battery is shown in section.

A lot of useful information on the choice of heating devices can be found by watching the video:

5 common editing mistakes

Of course, when installing a heating system, you can make much more than five flaws, but we will highlight the 5 most egregious ones that can lead to disastrous consequences. Here they are:

- wrong choice of heat source;

- errors in the piping of the heat generator;

- incorrectly selected heating system;

- careless installation of the pipelines and fittings themselves;

- improper installation and connection of heating devices.

A boiler of insufficient power is one of the typical mistakes. It is allowed when selecting a unit designed not only to heat the premises, but also to prepare water for the needs of hot water supply. If you do not take into account the additional power required to heat the water, the heat generator will not cope with its functions. As a result, the coolant in the batteries and the water in the DHW system will not heat up to the desired temperature.

Details play not only a functional role, but also serve security purposes. For example, it is recommended to install a pump on the return pipeline just before the heat generator, in addition to the bypass line. Moreover, the pump shaft must be in a horizontal position. Another mistake is to install a crane in the area between the boiler and the security group, this is strictly unacceptable.

Important. When connecting a solid fuel boiler, the pump must not be placed in front of three-way valve, but only after it (along the coolant).

The expansion tank is taken with a volume of 10% of the total amount of water in the system. With an open circuit, it is placed at the highest point, with a closed one - on the return pipeline, in front of the pump. Between them there should be a sump mounted in a horizontal position with the plug down. The wall-mounted boiler is connected to the pipelines by means of American women.

When the heating system is chosen incorrectly, you risk overpaying for materials and installation, and then incurring additional costs to bring it to mind. Most often, errors occur when installing single-pipe systems, when more than 5 radiators are tried to “hang” on one branch, which then do not heat. The flaws in the installation of the system include non-observance of slopes, poor-quality connections and installation of the wrong fittings.

For example, a thermostatic valve or a conventional ball valve is installed at the radiator inlet, and a balancing valve is installed at the outlet to adjust the heating system. If pipes are installed to radiators in the floor or walls, then they must be insulated so that the coolant does not cool down along the way. When joining polypropylene pipes, it is necessary to carefully adhere to the heating time with a soldering iron so that the connection is reliable.

Choosing a coolant

It is well known that filtered and, if possible, demineralized water is most often used for this purpose. But under certain conditions, such as periodic heating, water can freeze and destroy the system. Then the latter is filled with a non-freezing liquid - antifreeze. But you should take into account the properties of this liquid and do not forget to remove all gaskets from ordinary rubber from the system. From antifreeze, they quickly become limp and a leak occurs.

Attention! Not every boiler can work with non-freezing liquid, which is displayed in its technical data sheet. This must be checked upon purchase.

As a rule, the system is filled with coolant directly from the water supply through a make-up valve and a check valve. In the process of filling, air is removed from it through automatic air vents and Mayevsky manual taps. With a closed circuit, pressure is monitored by a pressure gauge. Usually, in a cold state, it lies in the range of 1.2-1.5 bar, and during operation it does not exceed 3 bar. In an open circuit, it is necessary to monitor the water level in the tank and turn off the make-up when it flows out of the overflow pipe.

Antifreeze is pumped into a closed heating system with a special manual or automatic pump equipped with a pressure gauge. In order for the process not to be interrupted, the liquid must be prepared in advance in a container of the appropriate capacity, from where it should be pumped into the pipeline network. Filling an open system is easier: antifreeze can simply be poured or pumped into an expansion tank.

Conclusion

If you carefully understand all the nuances, it becomes clear that installing a heating system in a private house on your own is quite realistic. But you must understand that this will require a lot of time and effort from you, including for monitoring the installation in the event that you decide to hire specialists for this.

The Prorab-snab company has been performing turnkey heating installations in private houses for more than 10 years.

Over the past years, we have gained invaluable experience with the most advanced technologies in the field of heating, water supply, sewerage and underfloor heating.

Our staff includes only proven and qualified installation engineers, who have dozens of excellently completed projects of various levels of complexity and scale.

The company "Prorab-snab" has all the necessary permits, permits and licenses to carry out installation work in a turnkey house in Moscow at a reasonable cost.

All our work is transparent and structured. Previously, we make a detailed calculation of the installation of home heating - a diagram, the cost of materials, work, etc. You have the opportunity to see and control the work process at all stages and, accordingly, you understand the structure of your costs.

Price list for services

| Name of works | Unit rev. | Cost of work (rub) | Dismantling (rub) |

| from | from | ||

| Home heating installation | |||

| Mounting heater(radiator, floor convector) | PCS. | 2 000 | 1 000 |

| Laying of the pipeline of the heating system up to DN32 | m. | 90 | 50 |

| Design radiator installation | PCS. | 4 000 | 2 000 |

| Installation of a convector built into the floor | PCS. | 2 500 | 1 500 |

| Installation of a wall-mounted boiler | PCS. | 8 500 | 2 000 |

| Installation of a floor boiler up to 40 kW | PCS. | 8 000 | 4 000 |

| Installation of a floor boiler from 40 kW | PCS. | 15 000 | 5 000 |

| Chimney installation (inside the boiler room, from the boiler to the stationary chimney) | p.m. | 2 000 | 500 |

| Installation of an indirect heating boiler | PCS. | 7 000 | 3 000 |

| Installation of a distribution comb (collector) in a boiler room, incl. connection to the boiler, installation of drain cocks and automatic air vents | PCS. | 4 500 | 2 500 |

| Installing and tying a security group | PCS. | 2 000 | 500 |

| Installation of the pumping group, incl. coarse filter, check valves and air vents. | PCS. | 3 000 | 1 000 |

| Installation of a three-way mixer with a servomotor | PCS. | 1 000 | 500 |

| Installation of a comb (collector) for radiator heating. | PCS. | 3 000 | 1 500 |

| Installation of a comb (collector) for underfloor heating. | PCS. | 3 000 | 1 500 |

| Installing a built-in distribution cabinet | PCS. | 1 500 | 750 |

| Installation of a surface-mounted distribution cabinet | PCS. | 500 | 300 |

| Installation of pipeline and risers (up to DN 32 inclusive) | m. | 90 | 40 |

| Installation of pipeline and risers (from DN 32) | m. | 120 | 50 |

| Mounting expansion tank heating/water supply up to 100 liters | PCS. | 2 000 | 500 |

| Installation of an expansion tank for heating / water supply up to 300 liters | PCS. | 2 000 | 1 000 |

| Installing a thermostat on a radiator | PCS. | 300 | 100 |

| Installation of make-up heating system | PCS. | 2 000 | 500 |

| Electrical installation and commissioning | |||

| Electrical work in the boiler room up to 40 kW, no more than 5 pump groups, incl. power supply connection to the boiler, pump groups, electrical wiring in boxes | PCS. | 6 000 | 1 500 |

| Water supply installation | |||

| Installation of water supply, incl. withdrawal of cold or hot water to water outlet | dot. | 900 | - |

| Installation of highways and risers, up to DN 32 (insulation is included in the cost of work) | PCS. | 100 | 50 |

| Installation of conclusions for a heated towel rail | PCS. | 2 100 | - |

| Sewer installation | |||

| Installation of a sewerage point, outlet for a plumbing fixture | PCS. | 1 000 | - |

| Installation of a sewer riser, up to DN 110, insulation is included in the cost of work | m. | 250 | - |

| Revision installation | PCS. | 1 500 | - |

| Ladder installation | PCS. | 2 000 | - |

| Service maintenance of heating systems | |||

| Departure of a specialist to diagnose the heating system and troubleshoot problems that can be fixed on the spot: | |||

| Moscow and Moscow Region up to 20 km from MKAD | is free | ||

| MO from 20 to 60 km from MKAD | is free | ||

| From the Moscow Ring Road to the borders of the Moscow Region | is free | ||

| Outside MO | Price negotiable | ||

| Annual maintenance of the wall-mounted boiler | 12 000 | ||

| Annual maintenance of the boiler up to 100 kW | 12 000 | When concluding an installation contract, the 1st year is free. | |

| Annual maintenance of the boiler from 100 to 300 kW | Price negotiable | When concluding an installation contract, the 1st year is free. | |

| Annual maintenance of the boiler from 300 to 1000 kW | Price negotiable | ||

| Annual maintenance of the boiler from 1000 kW | Price negotiable | ||

|

Have questions? Call! |

Stages of work on the installation of heating in a private house

After you contacted us, we begin to work according to the following algorithm:

1. Departure of a specialist to the object

for a preliminary consultation.

This is one of the most important stages in all work, on which the entire further process of installing heating in a private house depends. At this stage, his wishes are discussed with the Customer. Explanations are given regarding the validity of certain decisions. In the absence of a drawing or plan country house, our engineer measures the premises to create in the future a schematic diagram or a project for heating, water supply, sewerage and underfloor heating.

This is one of the most important stages in all work, on which the entire further process of installing heating in a private house depends. At this stage, his wishes are discussed with the Customer. Explanations are given regarding the validity of certain decisions. In the absence of a drawing or plan country house, our engineer measures the premises to create in the future a schematic diagram or a project for heating, water supply, sewerage and underfloor heating.

2. Project development

or schematic diagram of the entire system.

So, we have reached a preliminary agreement on the preparation of a commercial proposal for the installation of heating in a private house.

So, we have reached a preliminary agreement on the preparation of a commercial proposal for the installation of heating in a private house.

We draw up a schematic diagram of your system. It includes:

- scheme of the boiler room with all the main components and assemblies (boiler, pumps, boiler, etc.);

- placement of heating devices in rooms (radiators, floor convectors, etc.);

- warm floor zones;

- installation points for wiring cabinets, with pipeline routes;

- points of draw-off of cold and hot water supply, with pipeline routes;

- points and wiring of sewer pipes;

It should be noted that for objects with an area of more than 300 sq. m it is necessary to make a full-fledged project of all systems, because, as experience shows, a schematic diagram is not enough to display the whole picture. And at the stage of assembly and installation, some difficulties may arise.

3. Specification calculation

and preparation of a commercial offer (price, price list).

Based on the data obtained at the previous stages, our specialists begin to calculate the estimate for the installation of heating in a private house.

Based on the data obtained at the previous stages, our specialists begin to calculate the estimate for the installation of heating in a private house.

Here the financial wishes of the Customer are taken into account. It is worth noting that the market for engineering materials and equipment is very diverse. At first glance, the same product can be purchased at completely different prices. There is also a myth about “overpaying for a brand”. It, of course, has a grain of truth in its basis, but the so-called overpayment for the brand is not very significant.

Our task at this stage is to prepare the most balanced offer in order to low price installation of heating in a turnkey private house did not come at the expense of quality.

We are official dealers of leading European manufacturers, which gives us the opportunity to make offers that are significantly more profitable than our competitors.

After we have prepared prices and prices for the installation of heating in a private house and received consent from the Customer, a contract is signed for the supply of material and performance of work.

4. Supply of materials for heating,

water supply, sewerage and underfloor heating.

Our company has its own warehouse stocks and a fleet of vehicles, so the supply of materials for work at your facility is carried out as soon as possible.

Our company has its own warehouse stocks and a fleet of vehicles, so the supply of materials for work at your facility is carried out as soon as possible.

Within the Moscow region, delivery of equipment is free of charge.

Upon receipt of all materials and equipment, the Customer is provided with all the necessary documentation, namely:

- waybills for the delivered material,

- warranty cards,

- certificates and permits.

So, the equipment was delivered to the Customer at the facility. Without delay, we move on to the next, most important stage.

5. Installation of heating in a private house.

All work is carried out in accordance with the existing schematic diagram or project.

All work is carried out in accordance with the existing schematic diagram or project.

After all the elements have been mounted and installed, the system undergoes air pressure testing and hydraulic testing. This is necessary in order to identify and eliminate all shortcomings and avoid difficulties in the future. When installing heating in a private house, we use all our many years of experience and skill.

6. Maintenance of the boiler room and heating system.

Boiler room maintenance contract - free of charge.

An obligatory component of any autonomous system operating on main gas is a boiler house maintenance agreement. This is mandatory requirement Gorgaz (Mezhraygaz).

An obligatory component of any autonomous system operating on main gas is a boiler house maintenance agreement. This is mandatory requirement Gorgaz (Mezhraygaz).

Some organizations that install water heating at home shift the responsibility for concluding a boiler room maintenance agreement onto the shoulders of the Customer, explaining that it will be easier to work with a local gas service than with them. But in fact, the secret is that these organizations do not have special licenses and permits for servicing gas equipment.

It should be noted that the cost of annual maintenance of a boiler house in a gas industry can be quite high. We do not shift additional difficulties with the service contract to our Customers, but We provide an annual maintenance contract for free!

By choosing our organization as a contractor for the installation of heating in Moscow or the Moscow region, you get: